Load Building is the core functionality of Freight. The primary purpose of load building is to plan the transportation of goods from your warehouse to the customers, from your supplier to your warehouse, or from a supplier directly to your customer, in the most efficient and cost-effective manner.

Alternatively, you can employ this functionality for goods movement between your warehouses, or from warehouse to production environment and vice-versa.

Let’s take an example of an ABC transporting company which delivers customer orders using their transportation equipment, where shipping items requested by customers ABC faced various challenges.

Although there were multiple orders for the same location, each order was not enough to create a full truck load (FTL) even after consolidating the orders trailer capacity was available. Such inefficient optimization plans in load building resulted in ABC facing a huge loss over a course of time.

As the origin facility for orders included multiple buildings in different locations therefore during shipping it became extremely difficult to collect items from different locations and create a full truck load.

Arrow 3pl load building service (LBS) can help ABC resolve these challenges as it supports all activities necessary to optimise transportation load and shipment in following manner,

- Arrow3pl can re-plan previously optimised solutions,

- Arrow3pl helps in aggregating and splitting orders and moving orders forward and backward in time,

- Arrow3pl also supports shuttling inventories to different locations based on shipping requirements, so that full transportation shipments are created while respecting both inventory and transportation related constraints.

Arrow 3pl load building service provides cost savings to users by optimising vehicles used in transferring stock between origins and destinations in the transportation network.

How does LBS (Load Building Service) work?

Load building typically uses input data, supply data, plan level data i.e. transactional data or the master data defined at the load building application level to solve LBS workflow.

To solve a plan, the Master data which is static in nature and Transactional data dynamic in nature, after receiving the input data LBS (Load Building Services) analyse and processes it based on users’ constraints and predefined configurations.

It creates loads or shipments which are displayed using predefined output views such as grades and detailed views in the application. These loads and shipments are then provided as input to other applications for further processing.

Workflow of Shipment or Load Planning

Each time a supply chain planning optimization software receives all orders from different destinations and this information is loaded as input to the load building application then analyses the data and processes it to create shipments. These shipment details when approved by customers are provided to the transportation manager (TM).

TM reviews details received from the load building application and approves the shipment, the routing details generated by TM (transportation manager) are then sent to the shipping warehouse which then generates the outbound orders.

What is Load Optimization?

When you can’t properly figure out the most efficient arrangements of items inside the container your logistics operation goes through a series of challenges.

For instance you need more trips to complete delivery and it translates to higher fuel expenses than required, that’s why Load Optimization is so important and effective.

Load Optimization can save you transportation costs, improve delivery speed and make your customers happy but how does this strategy arrangement of items packages or palettes work? We will talk about all aspects of load optimization in logistics, for instance basic working mechanisms, influencing factors, benefits of optimization and the role of automation.

Let’s Look At The Different Capabilities of Load Building (LB)

- Order Consolidation and Order Priority:This capability helps when there are multiple orders for the same destination, but each order does not fill the truck load. Using this capability LBS (Load Building Services) consolidates multiple orders based on their priority and ships higher priority orders first. It provides planners complete control over the way orders are consolidated.

- Order Splitting: This capability helps when trailer/ container capacity is available even after consolidating multiple loads and the next order in line cannot be entirely shipped using the order splitting capability. LBS (Load Building Services) splits the next order in line to fill the trailer and then ships the remaining order quantity in a different load, and this improves load optimization.

- Pull or Push of Orders: This capability helps when all orders of the day are consolidated but there is still space left on the load, using the pull or push of orders capability LBS (Load Building Services) pulls right sized orders from subsequent days or pushes part of the day’s orders to subsequent days.

- Palletization: This capability helps when the item has multiple packaging levels and each level has different stacking and shipping rules using the palletization capability the planner can configure granular stacking in orientation rules these constraints are honoured during the palletization process

- Load containerization helps: When orders are palletised and need to be loaded on a trailer, considering equipment constraints, the load containerization capability considers pallet stacking rules such as stack weight, stack height etc, to ship the maximum volume.

- Inventory checking: This capability helps when shipping certain orders results in inventory violations, well some orders need to account for the anticipated production or quantity. Using the inventory check capability LBS (Load Building Service) combines orders that consume from inventory and projected inventory.

- Inventory shuttling: This capability helps when the origin facility consists of multiple buildings with stocks, sometimes these buildings facilities can be many miles apart, using the inventory shuttling capability LBS ensures the FTL (Full Truck Load) which is created from one location if possible if one facility cannot create an FTL then items need to be shuttled to make an FTL efficient.

- Multi Stop Loading: This capability helps when orders going to a destination cannot make an FTL (Full Truck Load) even after order pull or push using the multi stop loading capability, LBS combines the partial shipments to make one FTL (Full Truck Load) with multiple stops. However orders of different destinations are not mixed on the same stack.

- 3D Load Visualisation: This Capability provides a 3D view of the inventory loaded into the equipment from multiple angles such as top view, rear view, side view etc which allows the company to have a better look at the optimum utilisation of trailer’s load.

With these capabilities Arrow3 PL LBS (Load Building Service) improves load prioritisation planning and eliminates in-transit damages, reduces execution exceptions, increases throughput and reduces transportation cost, so load building with the help of its diverse features and capabilities helps create shipments from various orders and optimise transportation load.

What Methods Can We Use to Optimise Load Building?

- Using Load Planning Software: We can invest in load planning software to employ optimization procedures to proficiently categorise items according to their weight, size and destination.

- Organised Packaging: can encourage a way of organised packaging which will smoothen load building process and it will make it easier to set out items uniformly and maximise the use of available space.

- By Adopting Weight Distribution standards:We can put in place guidelines regarding weight distribution which will reduce the risk of in- transit damages.

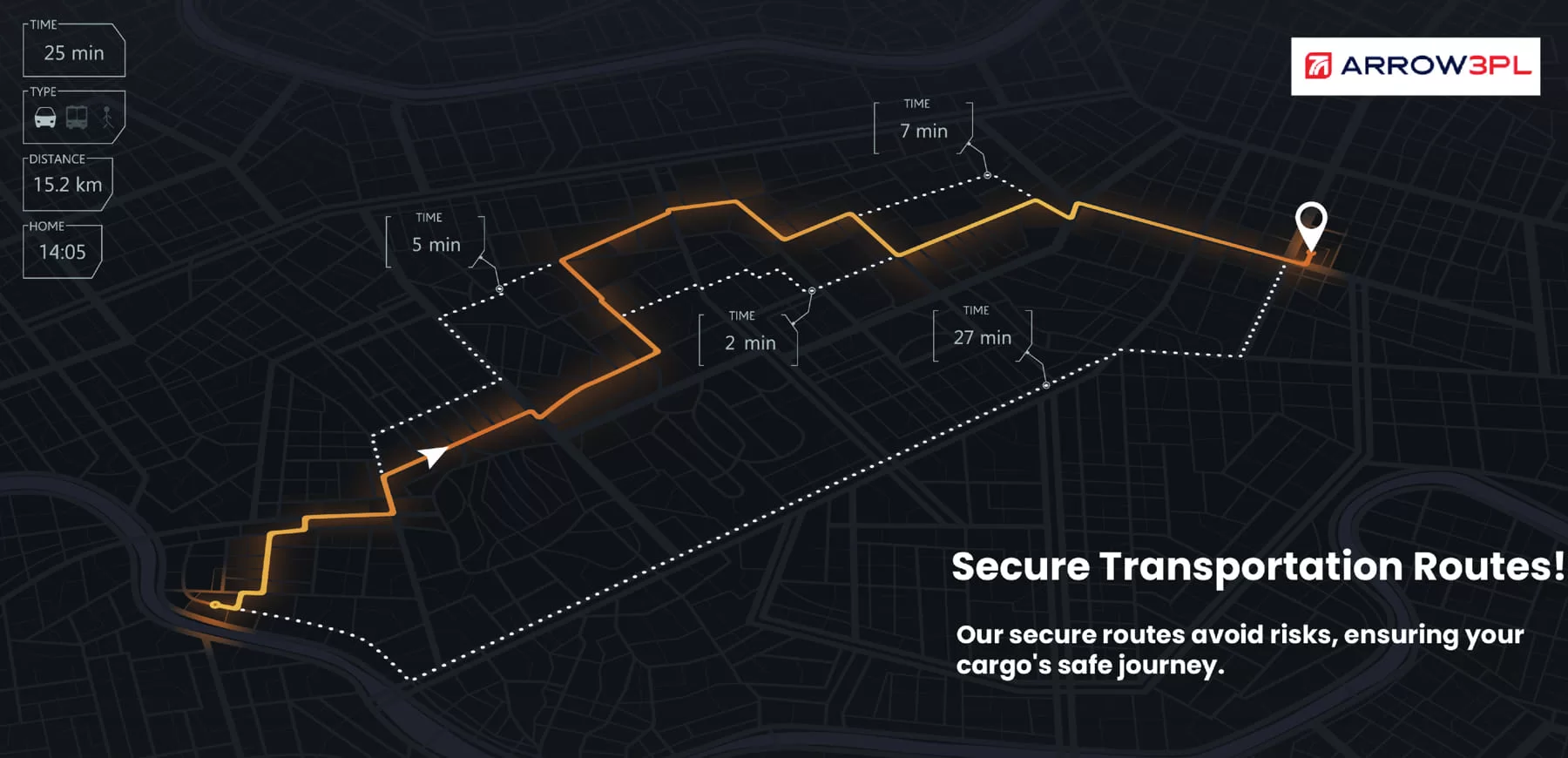

- Teaming-up with Suppliers and Distributors: by Working closely with suppliers and distributors we can straighten-up load building practices, share information, and optimise transportation routes.

- Considering Multi-Stop Routes: by Evaluating the viability of multi-stop routes and integrating shipments and curtailing empty space on vehicles we can enhance overall load efficiency.

- Eloquent Algorithmic Routing : putin effect dynamic routing algorithms can help us to adapt according to changing conditions, rerouting vehicles as needed when traffic or road closures, or delivery time windows pop up.

- Investing in Loading Equipment: by Utilising loading equipment and technologies which facilitate faster and more efficient loading, reducing interruption and improving operational efficiency.

Benefits of Load Optimization

- Huge Cost Saving on fuel by minimising the number of trips and maximising trailer capacity and manpower.

- Environmental Benefits by reducing fuel consumption and optimising transportation efficiency companies can lower their carbon emissions and contribute to sustained logistics practices.

- Improve Efficiency: by rearranging and repositioning items during every trip using simulation guided practices.

- Better Resource Utilisation: for any logistics company there are three major resources- vehicles, containers and labour with automatic load optimization.

- Flexibility and Adaptability: can help prepare for dynamic shipment related challenges in day-to-day operations.

In conclusion, Load Optimization is a crucial aspect of efficient logistics and supply chain management,and Arrow3pl’s Load Building Service (LBS) can address challenges faced by ABC Transporting Co. by offering diverse services such as order consolidation, palletization, and 3D load visualisation.

Load building Service enhances load prioritisation, while reducing transportation costs, and improving overall efficiency.

The benefits of optimization are vast, including cost savings, increased capacity utilisation, improved efficiency, reduced environmental impact, enhanced customer satisfaction, minimise risk of damage, optimised resource allocation, better compliance with regulations, adaptability to dynamic conditions, and streamlined supply chain operations.